Belts fail due to the following reasons, and primarily the first two

- Age

They're rubber + nylon, so after a while, the rubber and/or reinforcing material breaks down, causing the belt to come apart. Belts in this state can be described as "crispy" as the rubber looses pliability. - Pulley Problems

The belt rides over a number of pulleys to transmit the force of the crankshaft to other components. Problems such as poor alignment, wiggling (float), or a stuck (frozen) pulley will break a belt. - Obstruction

Stick + belt = broken. This is unlikely, but so is winning the lottery, and there's probably hundreds of lottery winners every day.

Proper Diagnosis

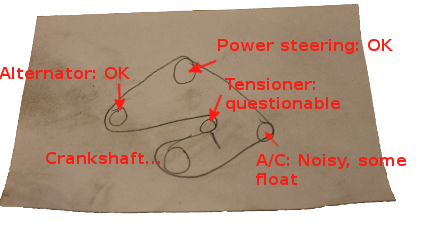

In my case, since the belt was new, #1 was ruled out, but number 2, well that's probably the problem. I checked the pulleys before replacement, here's my findings: |

| Annotated Belt Diagram |

The tensioner pulley was as stiffer than an old man's back and the AC pulley was noisy and presented some float. Float, in this sense, is when a pulley moves perpendicular with respect to its axle. I decided to take a chance a replace the tensioner: firstly, it was cheap (sub $10) and considering it looked the age of the car, I wasn't surprised it wasn't rolling quietly and smoothly. The next possible problem would be the A/C pulley, the float causing the belt to be incorrectly aligned and come-off the pulley, but that would be considerably more expensive, so lets start with the cheap fixes first.

Replacing the Tensioner Pulley

|

| Lots of room to remove part |

There's two other pegs (circled) on the tensioner to hold it in place, once mounted to the engine. This is neat design in that the tension cannot be incorrectly mounted and, at the same time, can be held in place with just one bolt, saving assembly time.

There's two other pegs (circled) on the tensioner to hold it in place, once mounted to the engine. This is neat design in that the tension cannot be incorrectly mounted and, at the same time, can be held in place with just one bolt, saving assembly time. As with the rest of the engine bay, the part was covered in oil. I'm sure that I'm leaking from the valve covers, and/or the cover over the timing chain and/or the camshaft seals. More leaks than an onion farm. As long as I don't have a puddle in my driveway, that's a problem for a different day.

|

| New (l) and Old (r) |

|

| Reassembled and much cleaner |

Re-assembled and the part was ready for re-installation. Considering how easy this change was to do, I should have done it when replacing the belt the first time around.

I'm happy that I took pictures as I went along, as I didn't know in which direction to install the new pulley -- but since I had a picture of the part right after removal, knowing what to do was easy.

Rattling Continued until it Stopped

Installed the belt, nothing notable there. Fired-up the engine and it ran just fine. But the A/C pulley was still rattling. Figured this was OK, drove the car for about a week and the A/C pulley became louder, developing into a legitimate, full-blown racket. The noise finally went away when the replacement belt broke, so I know what needs to be done to fix the root cause of the problem. I've never done any work on an A/C system, so this should be a learning experience.

No comments:

Post a Comment